Trackers

Trackers

Trackers

Trackers

Trackers

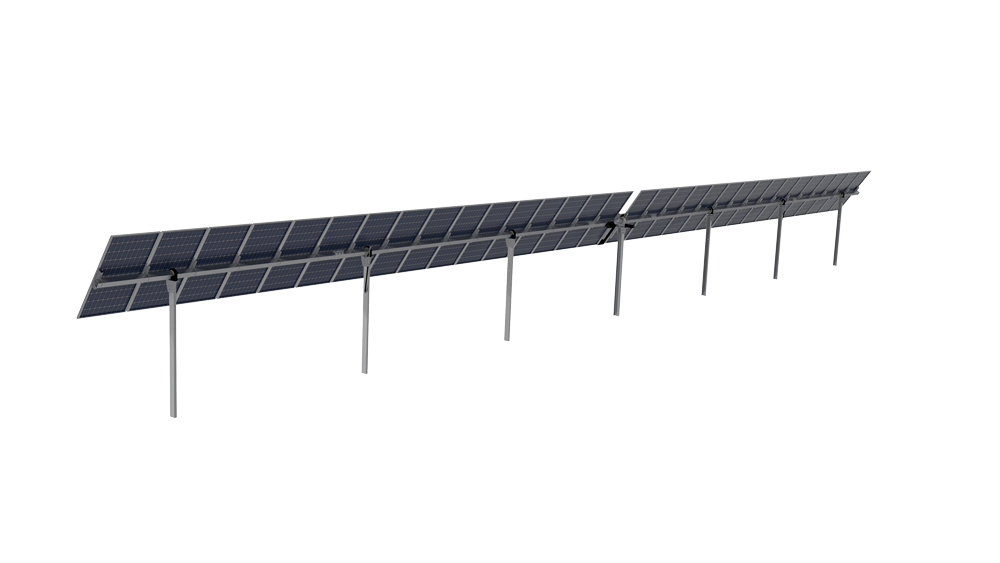

.The STT1 Trackers offer all the versatility when setting the modules up to make full use of the surface

The STT1 solar tracking solution makes it possible to optimise any solution to cover all kinds of needs in terms adaptating to lay-outs and different module configurations

Technical characteristics

| Technical characteristics | ||

|---|---|---|

| Structure type | .The STT1 is designed as a single row system, i.e., the built-in motor is directly related to a single axis. | |

| Angle | .The trackers rotate East-West throughout the day, with a +/- 55º tracking range | |

| Slope | .Maximum north-south slope is 12%, however, the east-west slope is unlimited. It also possible to adapt to other conditions. | |

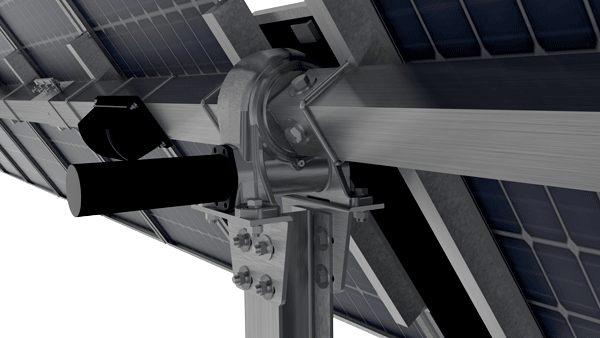

| Structure materials | .All the trackers use the following materials: HDG Steel S280, S355, S350GD ZM310 (Magnelis). The bearings however are made of polymeric, self-lubricating materials (requiring no maintenance.) | |

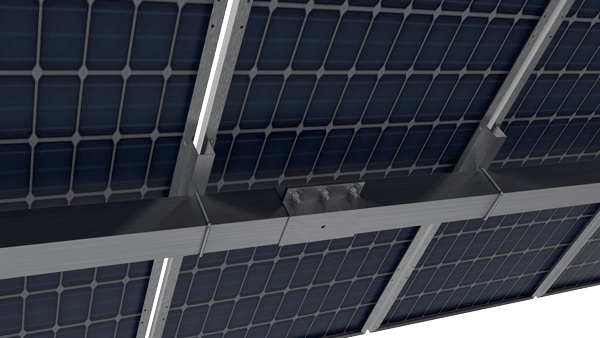

| Assembly | All the tracker joints are bolted, using GV class 10.9 bolts. | |

| Set-up | .The set-ups we have are 1V, 2V and 3H. | |

| Standards | .The wind codes/standards that have to be met are: Spanish Building Code (CTE), Eurocode, ASCE07, local standards | |

| Temperature range | .The tracker tolerates temperatures from -20ºC to +55ºC. | |

| Module fastening | .Depending on the tracker configuration, the modules are fastened by means of staples or screwed assemblies. | |

| Foundation | .Depending on terrain characteristics, the foundation can be direct pile driving, pre-drilled, foundation bolts or footings. | |

| Wireless communication | .Communication between the various control system elements is via Zigbee protocol. This is a wireless protocol, eliminating the need for communication cables between elements separated by large distance and reducing the likelihood of failure. | |

| Remote or on-site data | .The system includes an internet connection and an industrial PC where it is possible to view data. Data can also be viewed remotely, with an option to include a data viewing environment to make it easier for the customer to understand the data. | |

| Up to 200 solar trackers per control unit | .Each central control unit can control up to 200 individual tracker units, making it possible to produce large projects without needing additional central control units, helping to acquire data in a far more centralised way. | |

Bolted joints, no need for welding

Central post together with geared motor and tracking system

Predictive maintenance

Isolated or integrated

High yield

Control system

Efficiency

Backtracking

All terrain types